How to calculate manufacturing overhead Formula + examples

Manufacturing overhead costs are indirect costs related to the production of processes, while total manufacturing costs encompass both direct and indirect expenses. Once you have identified all of the manufacturing overhead costs, you need to choose a method for allocating them to products. Manufacturing overhead is referred to as indirect costs because it’s hard to trace them to the product. A final product’s cost is based on a pre-determined overhead absorption rate.

- Unite your marketing and development teams with dynamic collaboration, concurrent workflows, and data continuity throughout the entire product lifecycle.

- This is because manufacturing overhead costs are typically fixed, so they are spread out over a larger number of units when production volumes are high.

- Take your learning and productivity to the next level with our Premium Templates.

- These costs are necessary for the overall operation of the business, but they cannot be directly traced to each unit of production.

- Once you’ve estimated the manufacturing overhead costs for a month, you need to determine the manufacturing overhead rate.

- The product life cycle refers to the time period when a product is first introduced to a market until it exits the market.

What are manufacturing costs also known as?

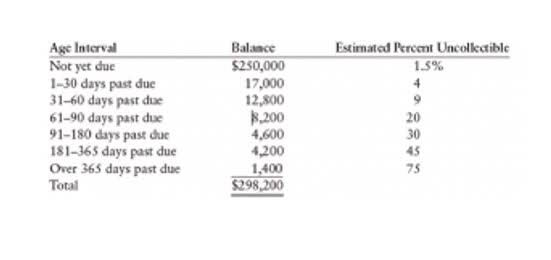

Thus, you first need to sum up all the indirect expenses that you incur. And then allocate such expenses using a specific measure to calculate the Overhead Rate. Now, we know that there are certain costs that increase with an increase in output and decrease with a decrease in output. However, there are certain overheads that do not vary with the change in the level of output. However, there are other costs that you cannot directly identify with the production of final goods. Such costs are the supplementary costs that you incur to facilitate your production process.

Examples of Manufacturing Overheads

To calculate manufacturing overhead, you need to identify and add up all of the indirect costs incurred during the production process. For example, the business might have general liability insurance, a business license, HR employees, office supplies, accounting and legal fees, bank fees, etc. The business has to pay these indirect costs even if they aren’t currently working on any projects. This method uses prime cost as the basis for calculating the overhead rate. Prime Cost is nothing but the total of direct materials and direct labor cost of your business.

AccountingTools

- Examples include office equipment, shipping and mailing costs, marketing, legal expenses, and maintenance.

- Besides, MRPeasy reduces inventory levels and stock-outs by saving data collection and planning time.

- Knowing how to accurately estimate these costs is essential for setting product prices, budgeting, and maintaining profitability.

- The higher the percentage, the more likely you’re dealing with a lagging production process.

- The items in this list might change over time along with the increasing or decreasing business activity.

- For example, utility costs typically include a base monthly delivery charge but also increase depending on how much heat, water, or power you use.

- Overhead refers to the ongoing business expenses not directly attributed to creating a product or service.

Now that you are familiar with the components that constitute manufacturing costs, let’s move on to the process of calculating these expenses. Manufacturing costs, also called product costs, are the expenses a company incurs in the process of manufacturing products. Selling overhead relates to activities involved in marketing and selling the good or service.

They remain the same at certain stages but increase based on production output. So, for example, insurance rates will typically include a base rate, with premiums then based on factors like is shipping cost manufacturing overhead performance. These fixed costs remain the same regardless of the company’s scale of production. Whatever quantity of goods the company produces, these overhead costs do not change.

What is Manufacturing Overhead Cost?

These are the expenses that stay the same even when production volume changes. The cost of your building rental, property taxes, and insurance are all fixed manufacturing overhead costs. Even if you make 100 bikes or 1,000 bikes, those costs will remain the same. We’ll review the different costs included in manufacturing overhead and what businesses should know about calculating their manufacturing overhead costs.

However, you need to first calculate the overhead rate to allocate the Overhead Costs. This Overhead Rate is then applied to allocate the overhead costs to various cost units. Direct costs, also called operating costs, are the costs of purchasing raw materials or inventory, cost of labor, or costs of providing services.

What’s included in manufacturing overhead costs?

- Semi-variable overhead expenses are costs that have a fixed baseline expense but may also fluctuate in relation to business activity.

- Overhead is a summary of the costs you pay to keep your company running, and appears on your monthly income statement.

- In other cases, legal costs can be variable—for example, if you need to bring in a legal expert to address a merger, lawsuit, or audit.

- These expenses are reported for the period for which they are incurred.

- Thus, advertising costs incurred on promoting your bakery products helps in the smooth running of your business.

With Skynova’s accounting software, it’s possible to quickly record expenses and categorize them so you know precisely where your money goes. Because manufacturing overhead is an indirect cost, accountants are faced with the task of assigning or allocating overhead costs to each of the units produced. This is a challenging task because there may be no direct relationship. For example, the property taxes and insurance on the manufacturing buildings are based on the assets’ value and not on the number of units manufactured. Yet these and other indirect costs must be allocated to the units manufactured.

Seven Ways to Reduce Your Manufacturing Overhead

If the base does not accurately reflect the way overhead is incurred, it can lead to mispriced products and misguided strategic decisions. For instance, correlating machine maintenance costs with downtime may signal preventive measures or equipment upgrades. Examining utility bills can reveal energy wastage patterns, prompting eco-friendly solutions. Deciphering overhead costs is a strategic tool for efficient manufacturing.

Leave a reply

Laisser un commentaire